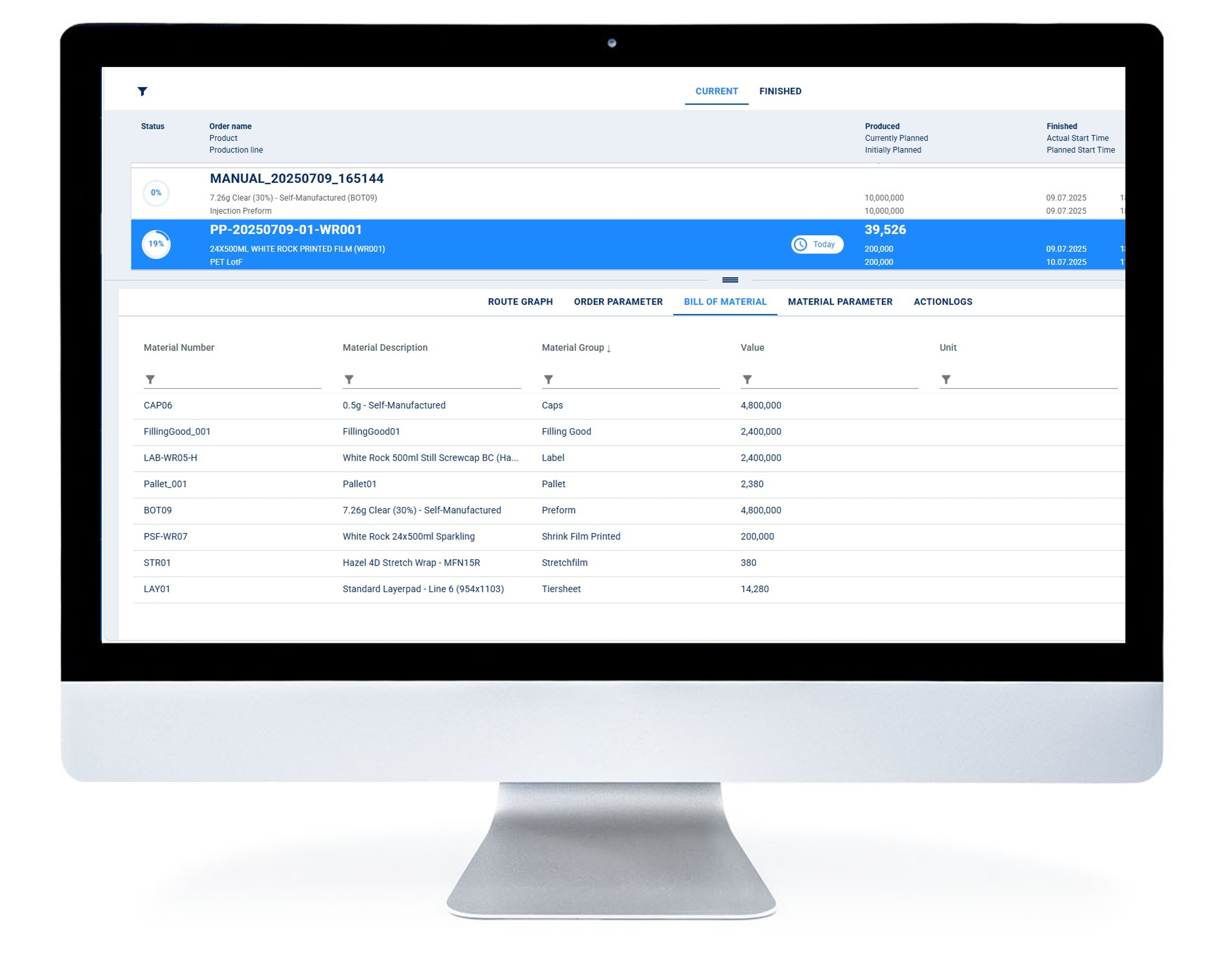

Automated order processing and material supply

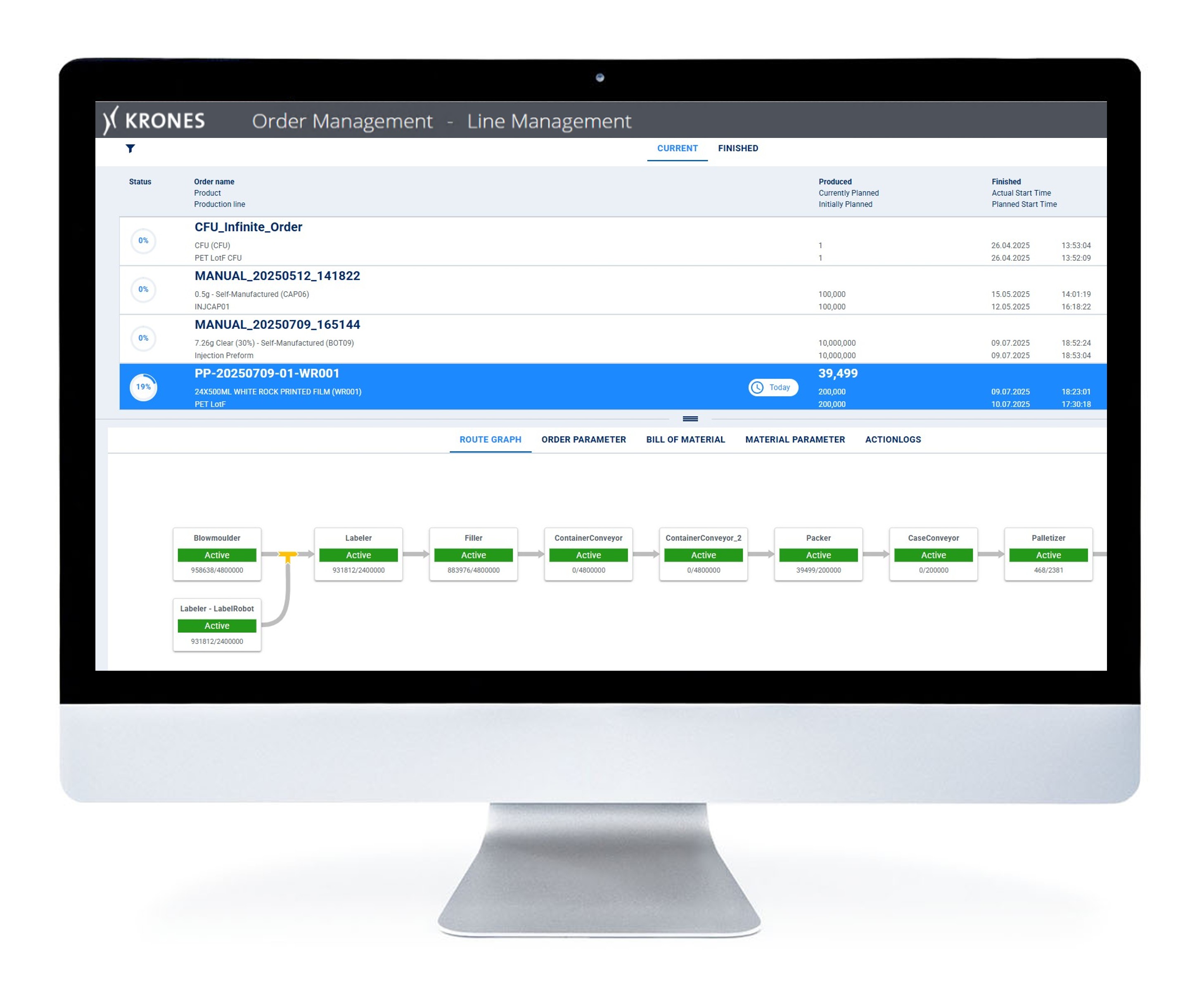

Line Management allows the entire filling and packaging process to be coordinated from a central position – from the definition of the order-specific production route to pallet labelling.

Seamless integration with Krones machines and other IT systems such as the ERP enables precise control of production along the entire line. To do so, the software considers your line to be a coherent system but not a row of isolated individual machines.

At a glance

With Line Management you can

- process orders automatically and keep changeover times consistently short.

- automate material requests and returns, which improves quality and avoids material losses.

- reduce manual effort and errors, as the system parameterises the machines and takes over communication and monitoring tasks.

- integrate label printers and coding devices into the line in order to automatically print important product information and best-by dates.

How Line Management works

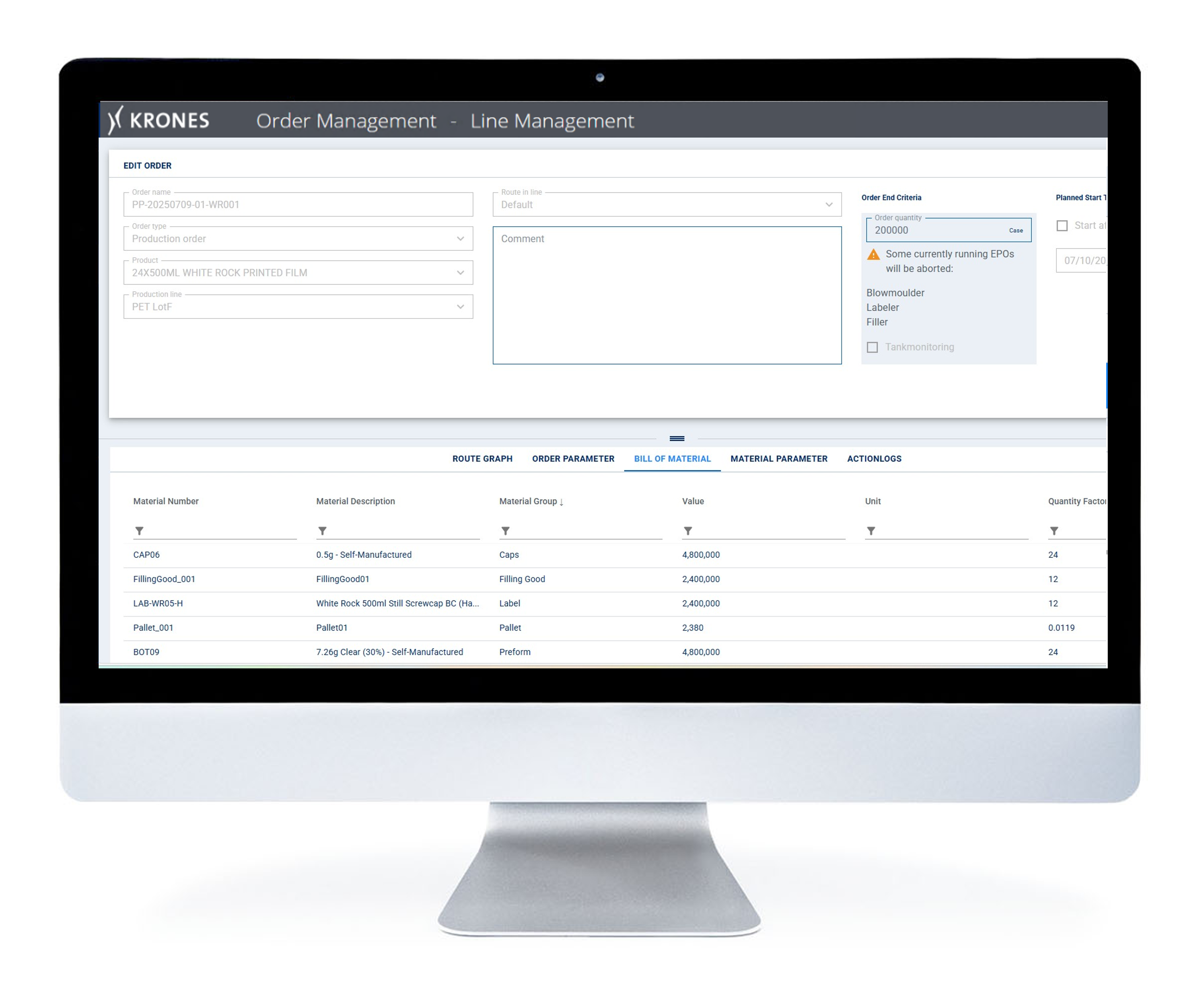

- Creating or importing work orders and Bill of Materials

- Precise processing of individual orders with different batch sizes and short reaction times

- Online routing: Determining the optimal route of the product within the line

- Automatic parameterisation of all affected lines and machines including the printer and coding devices

- Automatic termination of orders as soon as the tank is empty or a defined product quantity has been reached

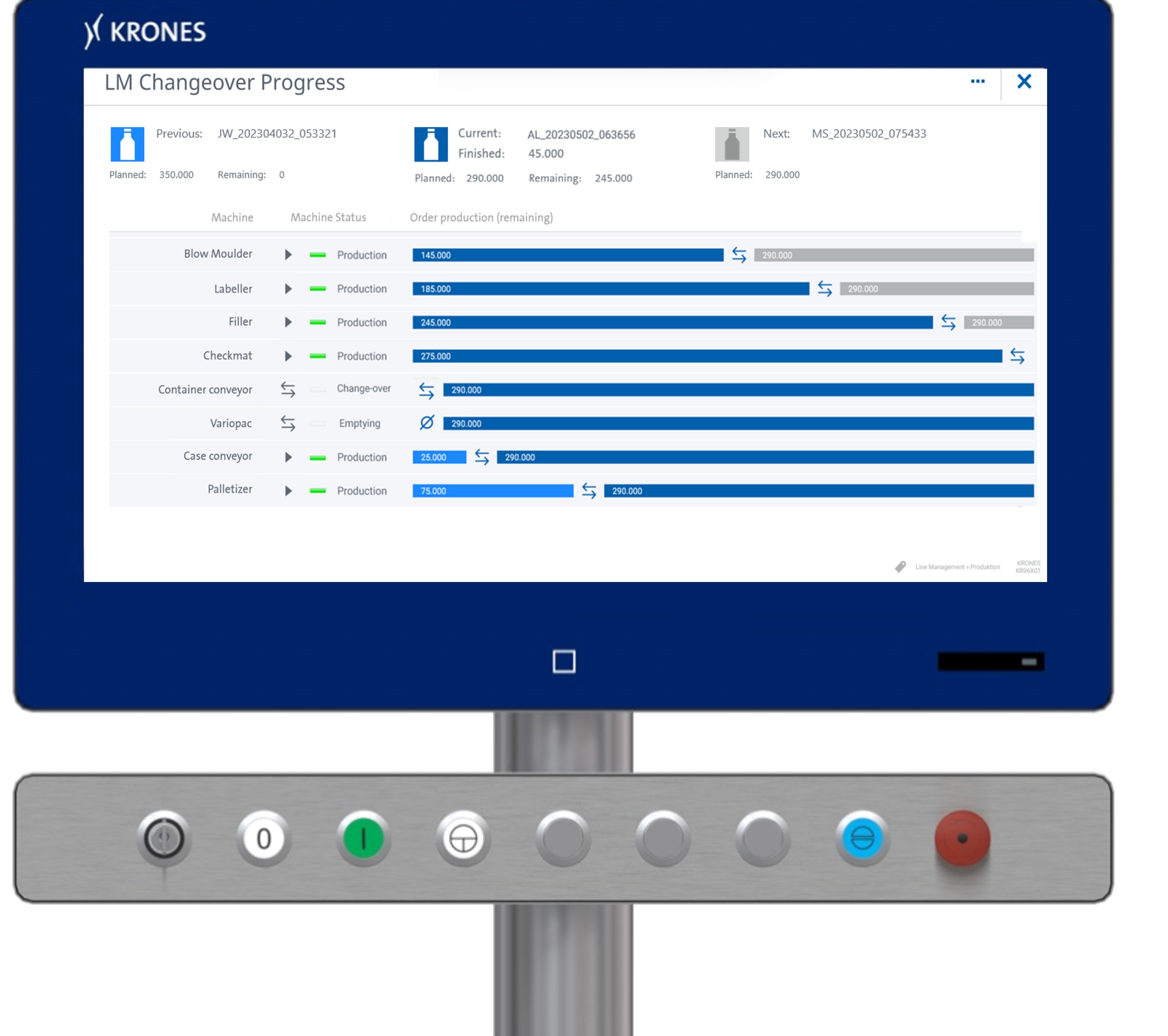

- Flying batch changes: Smooth transitions thanks to automatic empty runs, controlled start of the next order and controlled gaps between orders to avoid mix-ups

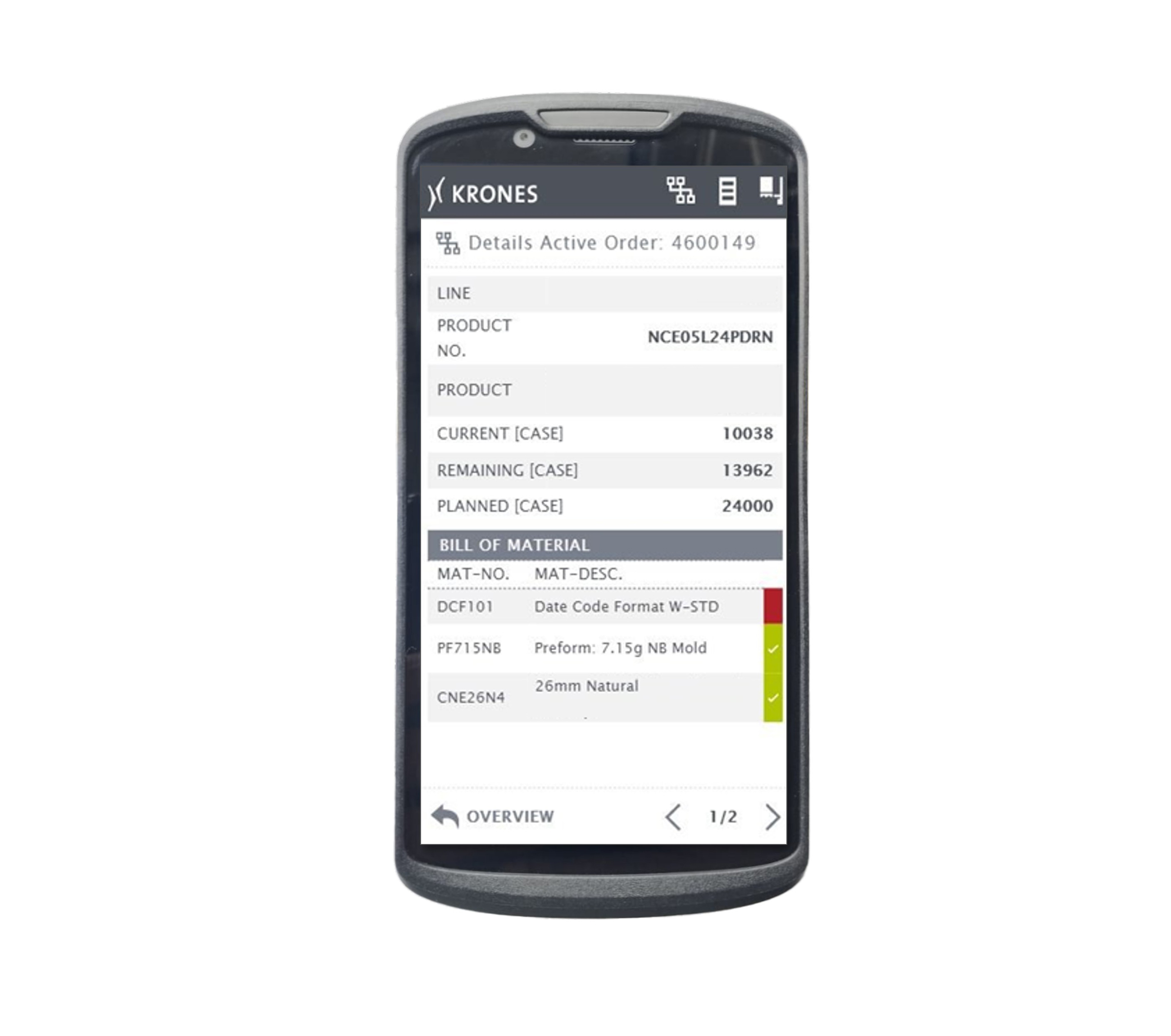

- Timely request and tracking of the right materials

- Standardised interface for seamless integration of third-party machines and customer IT systems

Module overview

Providing support in all areas of production

Benefits to you

Saving production costs

You optimise your consumption of resources by requesting all processing and operating materials always at the correct quantity and time.

Speed

Line Management optimises order processing. You benefit from reduced SKU changeover and cleaning times - even during the night shift.

Quality assurance

By automating and controlling production tasks, Line Management helps to significantly reduce your error potential and minimise rework.

Line availability

You benefit from maximum utilisation of your line thanks to parallel order processing with flying batch changeovers and batch aggregation per machine.

User-friendliness

Line Management impresses with its clear operator guidance, HMI and scanner integration and reduced manual labour.

Traceability

The software exactly records the production processes for each batch. You can exactly trace back each individual batch, even within quite complex product lines.