In Europe and elsewhere, the pressure to recycle more is increasing, as Dr. Michael Gotsche, Managing Director at Krones Recycling, explains: “Legislators demand higher proportions of recycled materials, trading companies set themselves ambitious sustainability targets and consumers expect transparency.” So there is meanwhile a growing awareness of the need to recycle not just PET bottles but to also feed more complex packaging like films or PET trays back into the plastics loop.

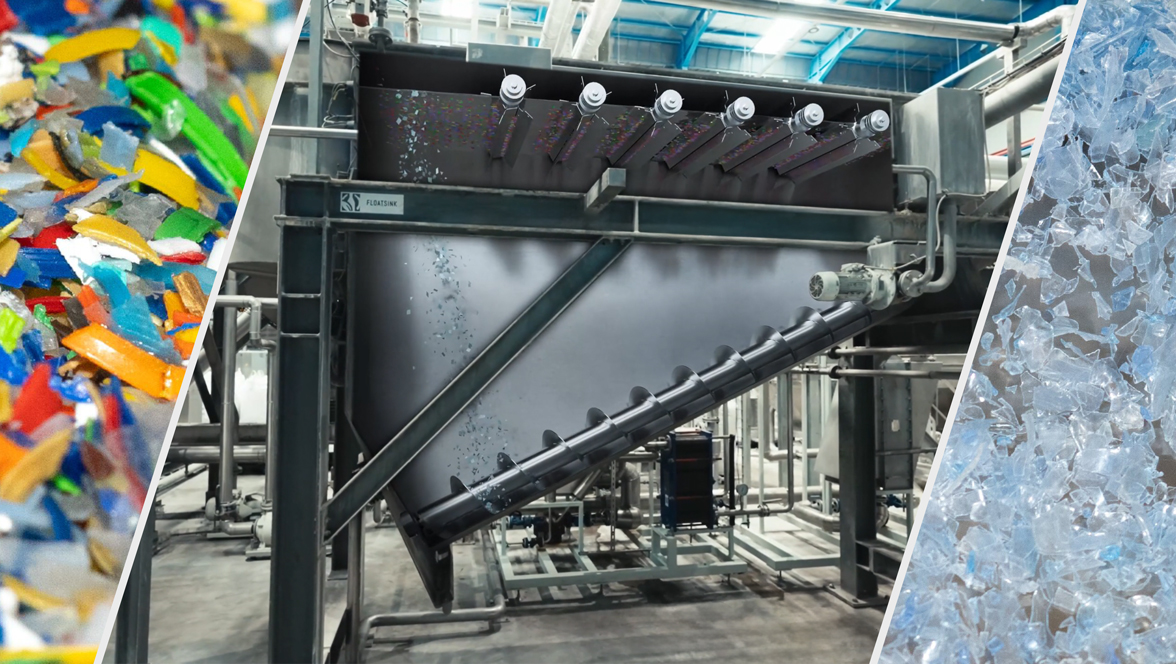

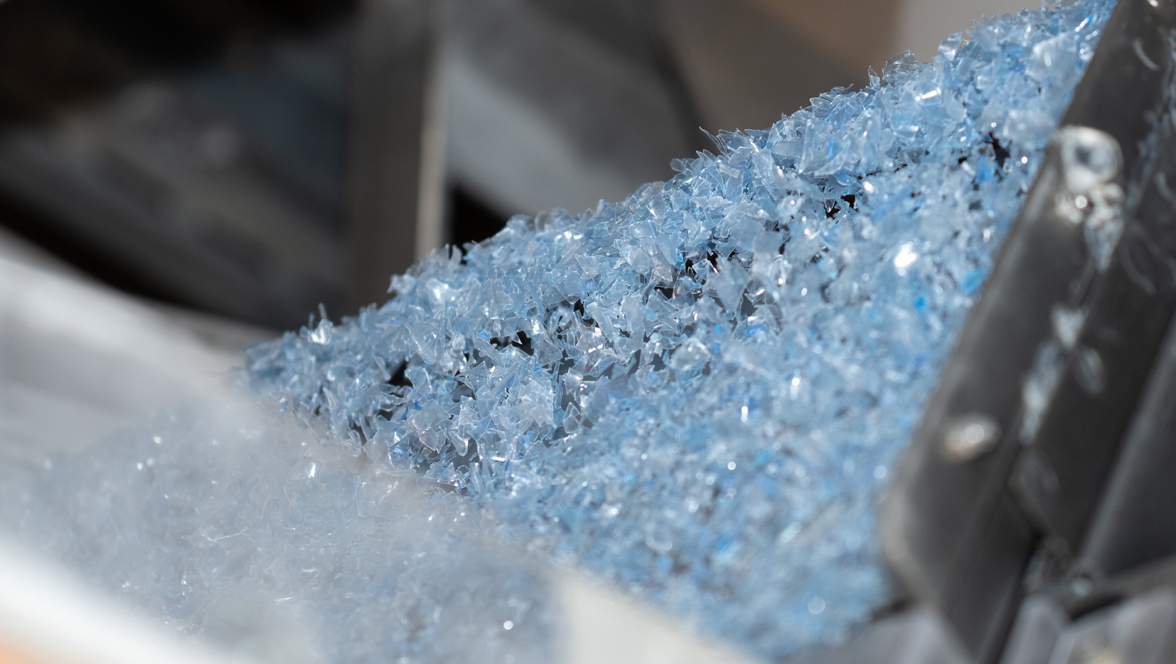

The key to accomplishing this lies in state-of-the-art recycling technologies. But that is precisely where several challenges have so far been looming: PET trays are often made of multilayer materials, contain barrier coatings, and/or are brittle or heavily soiled whereas flexible packaging is lightweight, thin and frequently consists of a combination of different materials that are difficult to separate. All of that leads to lower yields and poor-quality recyclate and means a large amount of these plastics are used for energy recovery instead of being recycled.