Production always right in view

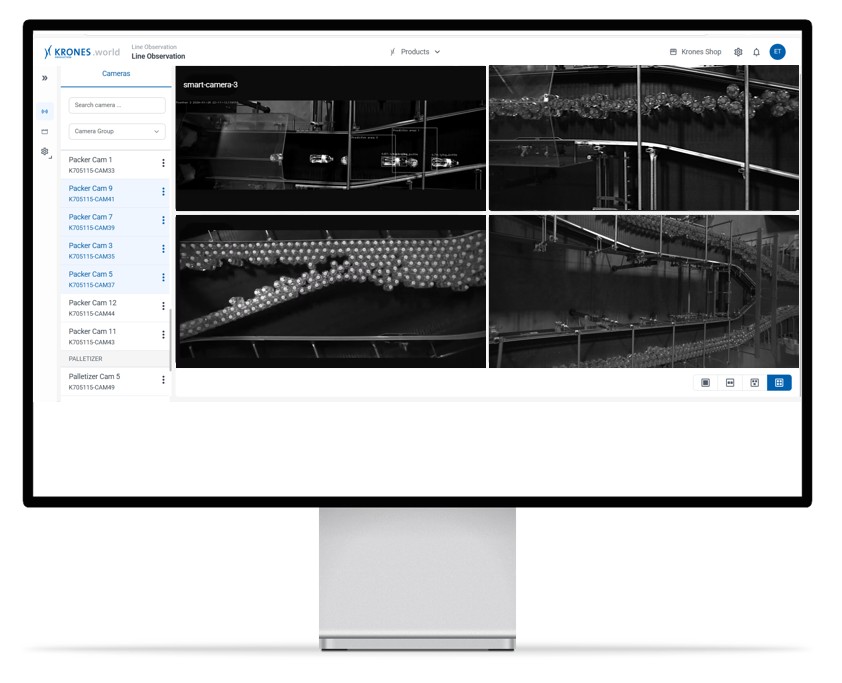

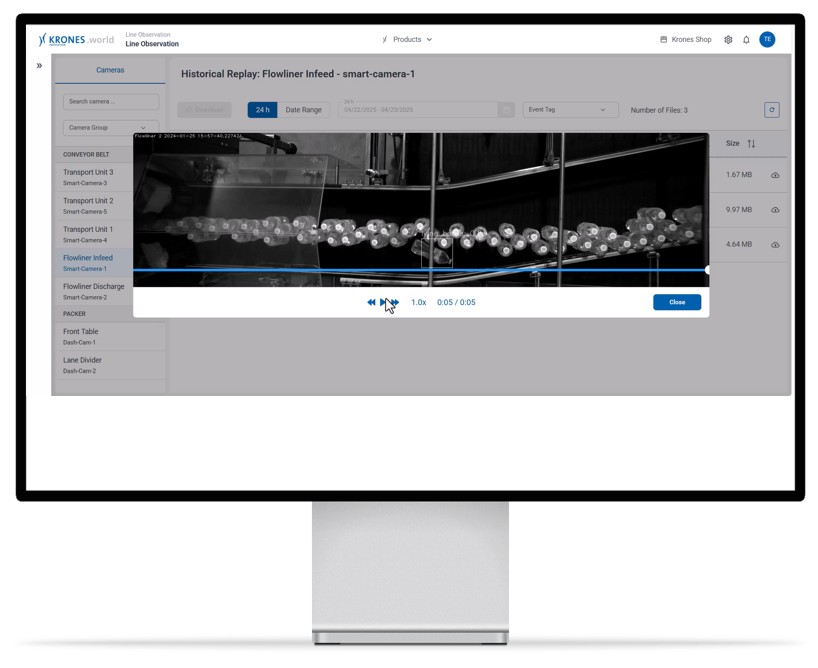

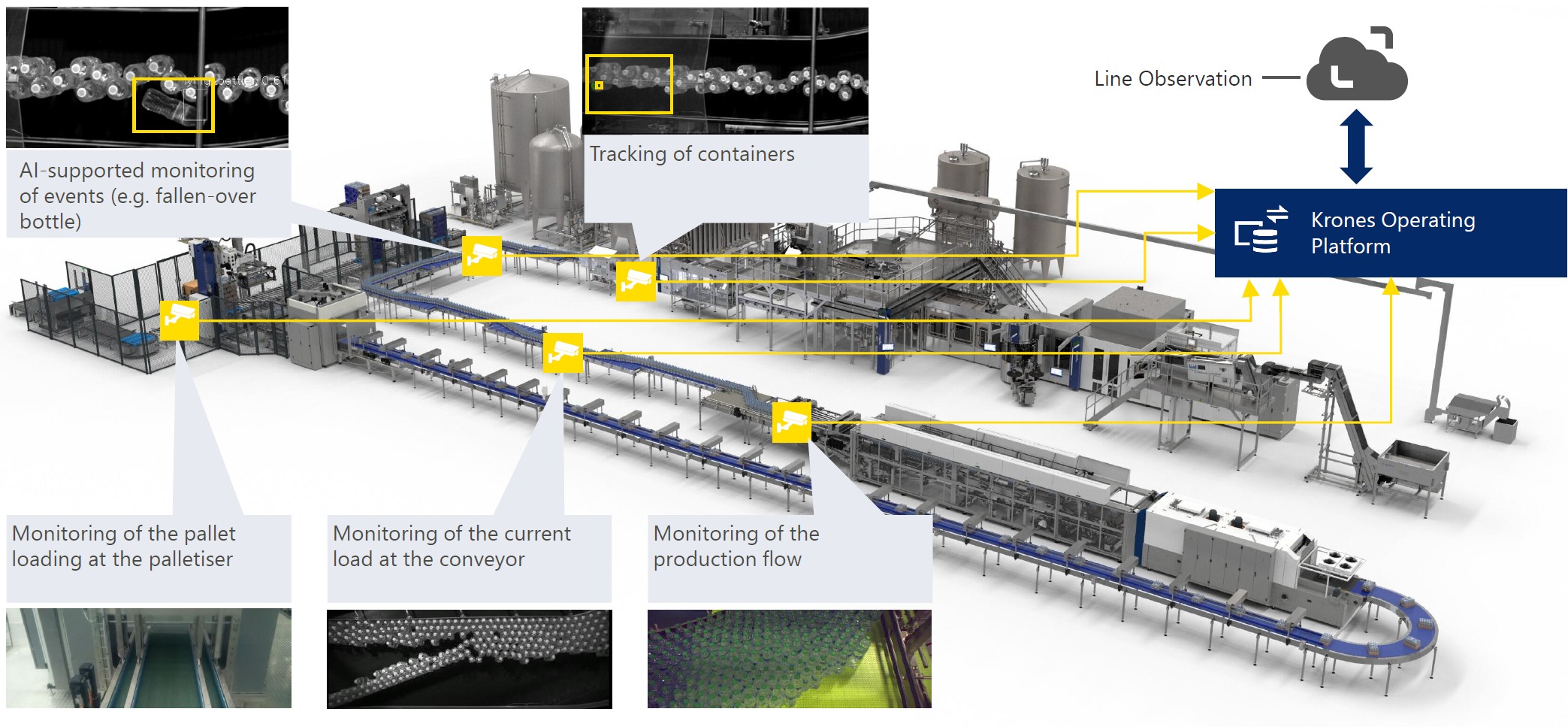

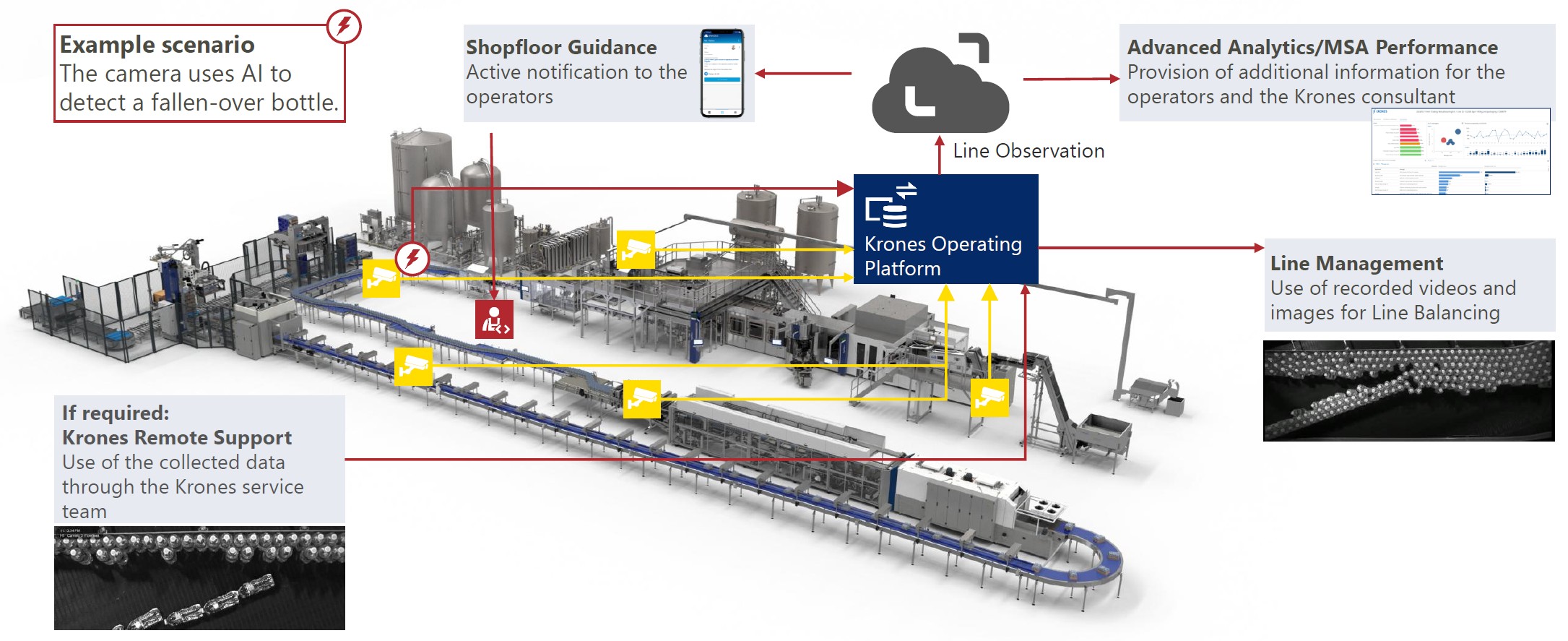

In the production line, various complex malfunctions can occur every day which your operating personnel cannot foresee or fully understand. Line Observation supports you here, as the solution monitors the complete production with modern camera systems. Live streaming, video recordings and AI-supported functions are used to precisely analyse malfunctions, machine standstills as well as the utilisation of your equipment and to initiate targeted measures. This increases productivity in the line without the need for personnel to be available directly at the machine.

At a glance:

- Tailor-made camera system: The complete production can be monitored

- Transparent and comfortable: The data from the production line is directly sent to the integrated systems

- Historical reproduction based on configurable events: Image and video sequences are collected and can then be played back and analysed

- Live monitoring on demand: A specific camera can be selected and a video livestream can be displayed for remote maintenance, immediate fault analysis and problem solution

This is how it works

Line Observation in detail

Possible interfaces with Krones solutions

Providing support in all areas of production

Benefits to you

Speed

Get an overview without delay and shorten the time it takes to react to malfunctions or unusual machine behaviour.

Remote monitoring

Get a live overview of dedicated machines without having to go directly to the affected areas of production.

Flexibility

Adapt Line Observation to exactly suit your requirements and the conditions in the line.

Security

Avoid downtimes and improve the OEE* of your machines by being able to react immediately to malfunctions in the line.

Integration

Benefit from perfect interaction between Line Observation and the existing digital services and systems of Krones.

Increased productivity

Recognise events in production quickly and accurately to increase line performance.