It's all about performance, efficiency and speed that perfectly matches any given situation. Even Krones’ fastest filling and packaging machines will achieve top output only when the individual process steps are interlinked by fit-for-purpose conveyor technology. So conveyors are much more than just transport routes for cans and bottles. Rather, they serve to control a line’s entire logistics. By intelligently distributing, guiding and buffering containers, they assure a harmonised product flow between the individual machines. That means that SynCo, Krones’ own container conveyor system, is nothing less than the discreet guarantor for a smoothly running operation.

Outstanding energy-efficiency

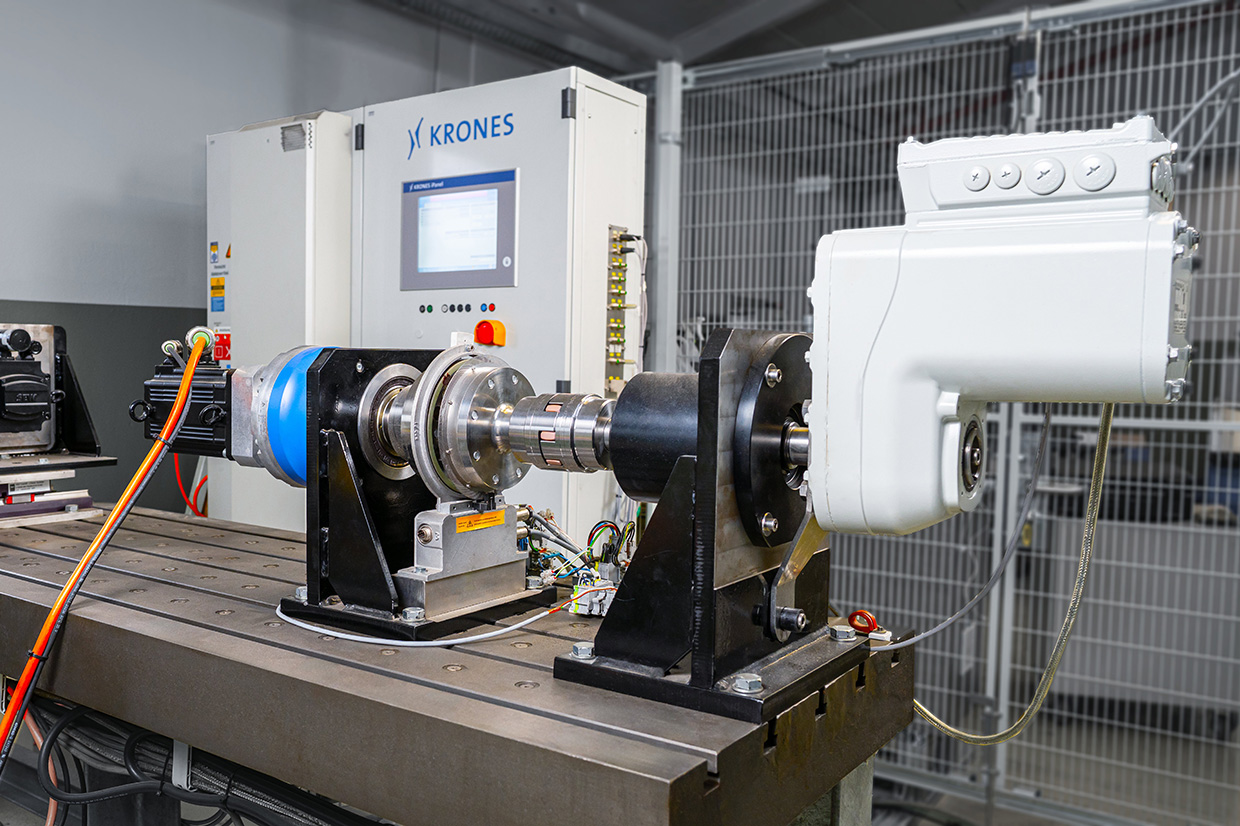

What sets SynCo conveyors apart is their electrified drive featuring permanent magnet motors, whose energy rating of IE5 (in accordance with IEC/TS 60034-30-2) represents the highest standard for motor efficiency. So these motors are in a league of their own. A brief digression into the world of synchronous and asynchronous motors helps to better understand the background here. Hartmut Davidson, Head of Machine and Control Drives in Neutraubling, has a degree in electrotechnical engineering and can draw upon 40 years of experience in this field. He explains it all to us: “In an asynchronous motor, the outer rotary magnetic field and the magnetic field in the rotor run asynchronously: The rotor rotates, in other words: drives the three-phase motor. But in order to create this magnetic field in the rotor, energy is needed which is then not available as drive power. Nor can the motor ever reach its full rpm, since induction is conditional upon a differential between rotor and outer magnetic field.”

In a three-phase synchronous motor, by contrast, the rotor contains permanent magnets which generate the requisite magnetic field so that it is not necessary to use energy for creating it. This type of motor, hence also known as permanent magnet motor (or PM motor for short), is therefore significantly more efficient and does not heat up so much as there is no slip. And Hartmut Davidson adds: “The fact that a PM motor cannot be directly connected to the mains but always needs a frequency converter does not limit its usability for Krones customers because all motors in Krones conveyors are frequency-controlled anyway.”