Krones.world brings together all our digital services on one unified platform. No more jumping between systems or searching for the right tool – everything you need is just a few clicks away. Whether it’s ordering spare parts, monitoring production, or accessing customer support, Krones.world is divided into three distinct areas that together make your digital experience simple, efficient, and seamless.

This sounds too good to be true? Get convinced by our experts who were speaking at the Krones Forum during drinktec by watching the video replay. They don’t just give you some information about Krones.world in general, but also cover topics like e-shop, production and customer service.

If you don’t have the opportunity to watch the video, we’ve summarized the three areas of Krones.world for you:

Krones.shop – Spare parts ordering made simple

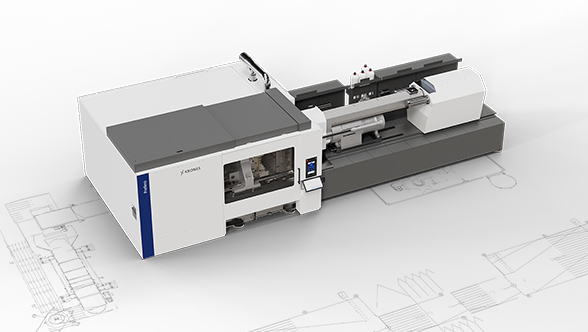

Need a spare part for your Krones machines or systems? With Krones.shop, the entire process – from inquiry and quotation to order and delivery – is transparent and straightforward. You can easily keep track of your orders and monitor their status online at any time. The personalised eCat helps you quickly find the right part, reducing errors and saving valuable time. Digital documents, including invoices, are always accessible, and for maximum efficiency, you can seamlessly integrate the ordering process into your own system. When speed matters most, Rapid Part On Demand enables you to print qualified spare parts directly on-site – making the future of spare parts supply a reality today.

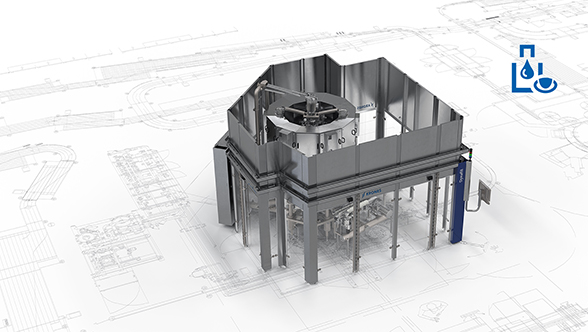

Krones.world Production – The digital connection to your machine

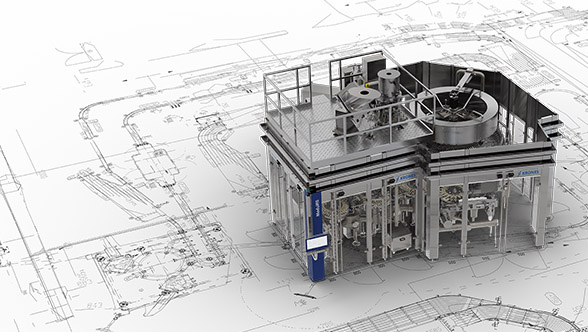

With Krones.world Production, our goal is to provide you with transparent, real-time monitoring of your entire production environment – whether via browser or directly at the machine’s HMI. Thanks to intelligent data connectivity, we help ensure your equipment stays up to date in terms of software and security. You can rely on smooth and secure operations, while additional digital services and remote consulting can be flexibly added to further boost the efficiency and availability of your line. And because we’re continuously developing Krones.world Production, you can look forward to even more digital services and features in the future.

Krones.world Customer Service – Always by your side

With Krones.world Customer Service, you have a clear overview of your individual support cases, service contracts, and all relevant documents at any time. Transparent dashboards keep you up to date on the status of your requests, while direct communication with the Krones support team – whether by phone, email, remote service, or directly through the portal – ensures that issues are resolved quickly and efficiently. As we move from reactive to proactive support, you benefit from expert assistance that monitors your systems, keeps your production reliable, and allows you to fully focus on your core business.

Dr. Anne-Kathrin Bräu企业传播

Dr. Anne-Kathrin Bräu企业传播 Pia Brunsch企业传播

Pia Brunsch企业传播 Valentina Catania区域企业传播专员

Valentina Catania区域企业传播专员 Celina Geldner市场营销和企业传播

Celina Geldner市场营销和企业传播 Sonja Grimm企业可持续发展

Sonja Grimm企业可持续发展 Angelika Krempl企业传播

Angelika Krempl企业传播 Julia Leber市场营销和企业传播

Julia Leber市场营销和企业传播 Julia Leserer企业传播

Julia Leserer企业传播 Peter Mörtl企业传播

Peter Mörtl企业传播 Gitta Rohling外部文案

Gitta Rohling外部文案 Christine Rüth外部文案

Christine Rüth外部文案 Patricia Thum市场营销和企业传播

Patricia Thum市场营销和企业传播 Aaron Wesolowski市场营销和企业传播

Aaron Wesolowski市场营销和企业传播